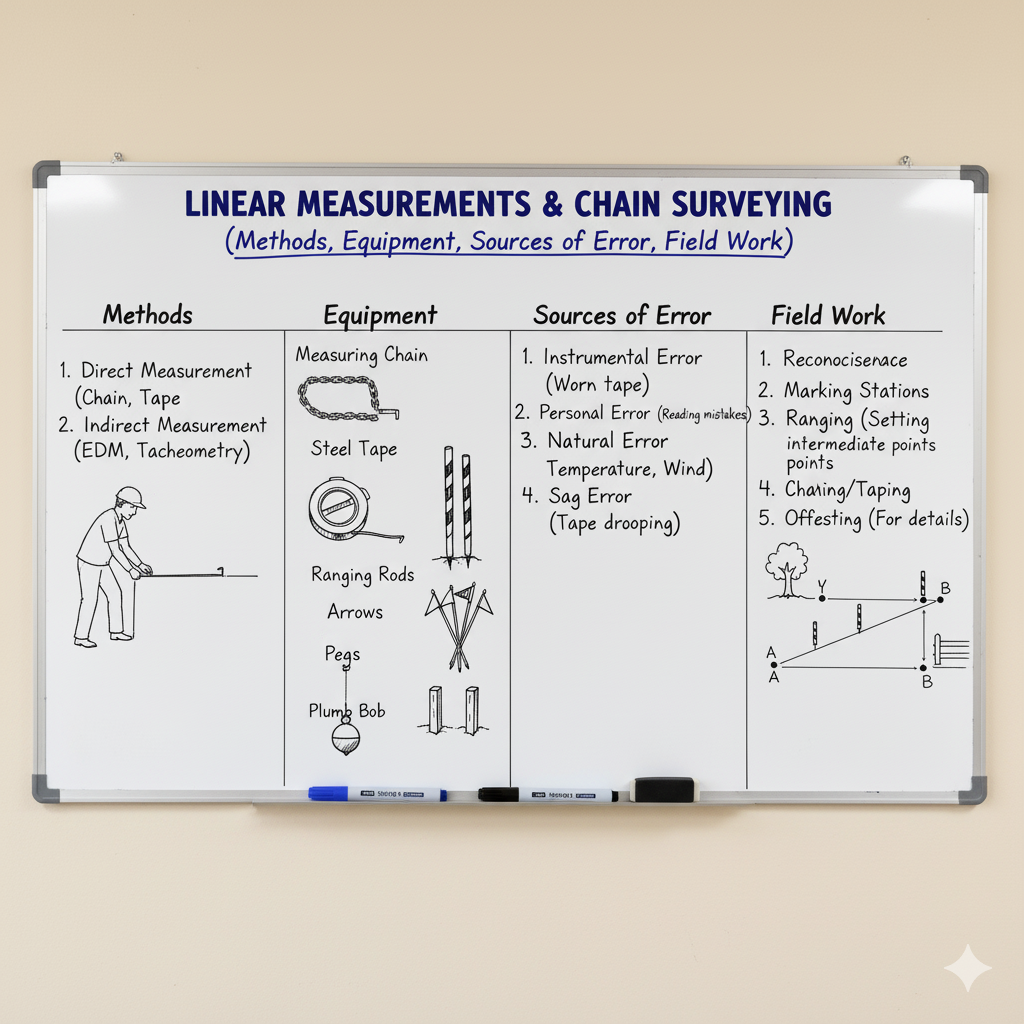

Linear measurement is the fundamental operation in surveying, involving the determination of horizontal distances between points. Chain surveying, a classic method, utilizes these linear measurements to map small, open areas with minimal detail. This infographic details the methods, instruments, potential errors, and practical aspects of linear measurements and chain surveying, crucial for foundational civil engineering practices. It also includes practice questions relevant to competitive exams like GATE and additional insights for civil engineers.

Methods of Linear Measurement

Linear distances can be determined using various approaches, ranging from direct physical measurements to advanced electronic techniques.

| Method | Description | Primary Tools |

|---|---|---|

| Direct Measurement | Physical measurement of distances using tapes or chains laid directly along the line. This is the most basic and common method. | Chains, Tapes |

| Indirect Measurement | Determining distances by measuring angles or other parameters and then calculating the linear distance using trigonometric principles. | Theodolite, Tacheometer |

| Electronic Measurement | Using electronic instruments that emit and receive electromagnetic waves to measure distances rapidly and with high precision. | Electronic Distance Meter (EDM), Total Station |

Key Instruments for Linear Measurement

The accuracy of linear measurements heavily depends on the precision and proper use of specialized instruments.

| Instrument | Description | Usage in Linear Measurement |

|---|---|---|

| Chains | Composed of steel links joined by rings, typically 20m or 30m long. Used for rough to moderate precision measurements. | Basic direct distance measurement in chain surveying. |

| Tapes | Flexible strips of steel, linen, or fiberglass, available in various lengths (e.g., 15m, 30m, 50m). Offer higher precision than chains. | Precise direct distance measurement, offset measurements, setting out. |

| Ranging Rods | Wooden or metallic poles, 2m or 3m long, with alternating bands of color (red and white or black and white). | Establishing intermediate points along a survey line, ranging. |

| Arrows | Steel pins, 25cm-50cm long, pointed at one end and looped at the other. | Marking chain lengths or tape ends on the ground. |

| Pegs/Wood Stakes | Wooden or metallic pegs driven into the ground to mark survey stations or other critical points. | Establishing permanent or temporary survey stations. |

| Optical Square/Cross Staff | Used for setting out perpendicular lines (offsets) quickly and accurately from a chain line. | Establishing right angles for offset measurements. |

Errors in Linear Measurement

Despite careful execution, errors are inherent in all measurements. Recognizing and mitigating these errors is vital for accurate surveying.

| Error Type | Description | Example/Cause |

|---|---|---|

| Systematic Errors | Errors that follow a consistent pattern and magnitude, often due to instrument imperfections or natural conditions. They are cumulative and can be corrected by formula. | Tape being too long/short, temperature variations, sag, pull, slope. |

| Random Errors | Errors that occur irregularly and are unpredictable in sign and magnitude. They tend to cancel out over many observations. | Inconsistent pulling of tape, inaccurate marking of ends, estimation errors. |

| Mistakes/Blunders | Large, uncorrected errors caused by carelessness, misunderstanding, or fatigue. They are typically significant and must be detected and eliminated. | Misreading a tape, miscounting chain lengths, wrong entry in field book. |

Fundamentals of Chain Surveying

Chain surveying is a method of surveying in which only linear measurements are taken, typically for smaller areas where high precision in angular measurement is not required.

Principles of Chain Surveying

- The fundamental principle is triangulation: breaking down the survey area into a network of interconnected triangles.

- Each triangle must be well-conditioned (angles not less than 30° and not more than 120°) to ensure accuracy.

- Only linear measurements are taken; no angular measurements are recorded directly.

Key Terminology in Chain Surveying

| Term | Definition | Visual Representation |

|---|---|---|

| Main Station | Major points at the boundaries of the survey area, forming the main framework. | ⚫ |

| Tie Station | Intermediate points on the main survey lines, used to locate nearby details. | ◼️ |

| Main Survey Line | The longest line in the survey, forming the backbone of the triangulation system. Also known as the Base Line. | ━━━━━━ |

| Tie Line | A line joining two tie stations or a main station and a tie station. Used to check the accuracy of the main lines and to locate details. | —- |

| Check Line | A line within a triangle, measured to verify the accuracy of the main survey lines forming the triangle. Its length provides a check. | ••• |

| Offsets | Lateral measurements taken from the main survey line to locate ground features (buildings, trees, etc.) at right angles or obliquely. | ⟂ or ↗️ |

Field Work Steps in Chain Surveying

The process of conducting a chain survey involves a sequence of systematic steps to ensure comprehensive data collection.

- Reconnaissance: Preliminary inspection of the area to identify suitable main stations and establish a framework of well-conditioned triangles.

- Marking Stations: Fixing main and tie stations on the ground with pegs or arrows.

- Running Survey Lines: Laying out the main survey lines (baselines and tie lines) on the ground.

- Measuring Chain Lines: Accurately measuring the lengths of all main and tie lines using a chain or tape.

- Taking Offsets: Measuring the perpendicular or oblique distances from the chain lines to locate ground features. Offsets should generally be short (e.g., up to 15m for accurate plotting).

- Field Book Recording: Meticulously recording all measurements and observations in a field book, often with sketches.

Overcoming Obstacles in Chain Surveying

Surveying often encounters obstacles that hinder direct measurement or sighting. Specific techniques are employed to overcome these challenges.

| Obstacle Type | Description | Solution Method |

|---|---|---|

| Obstacle to Chaining Only | Situations where a direct measurement along a line is impossible, but the ends of the line are visible from each other. | Bypassing the obstacle using a perpendicular offset method, similar triangles, or swinging an arc. |

| Obstacle to Ranging Only | Situations where the ends of a line are not visible from each other, but chaining is possible. This occurs due to intervening high ground. | Reciprocal ranging (ranging from both ends simultaneously) or using a random line method. |

| Obstacle to Both Chaining & Ranging | Situations where neither direct measurement nor direct sighting between two points is possible (e.g., a building, a large pond). | Establishing an auxiliary line or triangle around the obstacle, or using the principle of similar triangles. |

GATE Exam Practice Questions & Explanations

Test your understanding of Linear Measurements and Chain Surveying with these practice questions, commonly encountered in civil engineering competitive exams like GATE.

1. Which type of error in chaining is cumulative and can be corrected by formula?

Answer: Systematic Error

Systematic errors are constant in sign and magnitude and thus accumulate over measurements. They can be precisely quantified and corrected using specific formulas.

2. The process of breaking down the survey area into a network of interconnected triangles is known as:

Answer: Triangulation

Triangulation is the fundamental principle of chain surveying, where the area is divided into a series of well-conditioned triangles, and their sides are measured directly.

3. If a 30m tape is too short by 0.05m, the measured length will be:

Answer: More than the actual length

If the tape is shorter than its nominal length, it will indicate a larger reading for a given actual distance, making the measured length appear more than it is.

4. What is the primary purpose of a check line in chain surveying?

Answer: To verify the accuracy of the main survey lines.

A check line is an extra measurement taken within a triangle to ensure that the previously measured main lines and their intersections are accurate.

5. Which correction in linear measurement is always negative?

Answer: Sag Correction and Slope Correction

Both sag and slope cause the measured distance to be longer than the true horizontal distance, hence their corrections are always subtracted (negative).

6. An intermediate point on the main survey line, used to locate nearby details, is called a:

Answer: Tie Station

Tie stations are established along the main survey lines to facilitate the measurement of details that are close to those lines.

7. What is a “well-conditioned” triangle in chain surveying?

Answer: A triangle with angles not less than 30° and not more than 120°.

Well-conditioned triangles minimize errors in plotting and calculation, as small errors in measurement will have less impact on the shape and size of the triangle.

8. The error due to incorrect ranging is an example of which type of error?

Answer: Systematic Error

If ranging is consistently incorrect (e.g., always slightly off to one side), it will introduce a systematic error in the measured distance.

9. Which instrument is used to set out perpendicular lines from a chain line quickly?

Answer: Optical Square or Cross Staff

These instruments are specifically designed for establishing right angles on the field, which is essential for taking offsets.

10. What is the standard length of an offset in chain surveying to maintain accuracy?

Answer: Generally up to 15m (short offsets)

Longer offsets increase the potential for errors in locating features, so shorter offsets are preferred for higher accuracy.

11. A tape that stretches under tension will yield a measured distance that is:

Answer: Less than the actual length.

If the tape stretches, its markings become more spaced out, causing it to read a smaller value for a given true length.

12. Reconnaissance in chain surveying primarily involves:

Answer: Preliminary inspection of the area to identify suitable main stations and framework.

Reconnaissance is the initial survey of the site to understand its topography, identify obstacles, and plan the most efficient chain lines.

13. The longest line in a chain survey, forming the backbone of the triangulation system, is known as the:

Answer: Base Line

The base line is the most accurately measured line in the entire survey, forming the reference for all other measurements.

14. What is the purpose of applying temperature correction to a measured distance?

Answer: To account for the expansion or contraction of the measuring tape due to temperature changes.

Tapes are calibrated at a specific temperature. Deviations from this temperature cause changes in the tape’s actual length, requiring a correction.

15. When a line cannot be chained but its ends are visible, the obstacle is one of:

Answer: Obstacle to Chaining Only

This scenario allows for indirect methods to determine the length, such as constructing a perpendicular or similar triangle, as sighting is not an issue.

16. What are blunders in surveying?

Answer: Large, uncorrected errors caused by carelessness or misunderstanding.

Blunders are significant mistakes that can severely affect accuracy and must be detected and eliminated through careful checks and re-measurements.

17. Which instrument is used to mark the end of a chain length on the ground?

Answer: Arrows

Arrows are steel pins inserted into the ground to precisely mark the end of each tape or chain length during measurement.

18. The method of measuring distances on sloping ground by holding the tape horizontally in short stretches is called:

Answer: Stepping

Stepping is a technique used on sloping ground where the tape is held horizontally in small increments, allowing for direct measurement of the horizontal distance.

19. If the measured length of a line on a slope is L and the difference in elevation between its ends is h, the slope correction is approximately:

Answer: h2 / (2L)

This is the approximate formula for slope correction, derived from the Pythagorean theorem for small slopes, which reduces the inclined measured length to its horizontal equivalent.

20. The final step in chain fieldwork involves:

Answer: Meticulously recording all measurements and observations in a field book.

Accurate and organized recording in a field book is crucial for later plotting and analysis of the survey data.

More Info for Civil Engineers: Beyond the Basics

For civil engineers, mastering the fundamentals of linear measurements and chain surveying is just the beginning. Practical application and advanced considerations are paramount for real-world projects.

- Precision vs. Accuracy: Understand the difference. Precision refers to the closeness of repeated measurements to each other, while accuracy refers to the closeness of a measurement to the true value. Both are critical.

- Importance of Field Book: A well-maintained field book is a legal document. It must be clear, concise, and complete, containing all readings, sketches, and remarks. Illegible or incomplete field data can render an entire survey useless.

- Minimizing Cumulative Errors: For long survey lines, it’s essential to apply all necessary corrections (temperature, pull, sag, slope) to each segment to prevent cumulative systematic errors from propagating and significantly affecting the final distance.

- Limitations of Chain Surveying: While foundational, chain surveying is unsuitable for large, undulating, or densely built-up areas. It’s best for small, relatively flat, open sites. For complex terrains or high precision, advanced methods like Total Station and GPS/GNSS are indispensable.

- Digital Field Data Collection: Modern surveying often involves electronic data collectors that interface directly with instruments like Total Stations. This streamlines data capture, reduces manual errors, and allows for direct import into CAD/GIS software for processing.

- Quality Control in Practice: Always perform independent checks (e.g., using check lines, measuring diagonals) to verify the accuracy of your work. This proactive approach helps detect blunders early and ensures the reliability of the survey data for design and construction.